Standard costing and kaizen

Summary by Kerry A.

How a Japanese Auto Maker Reduces Costs

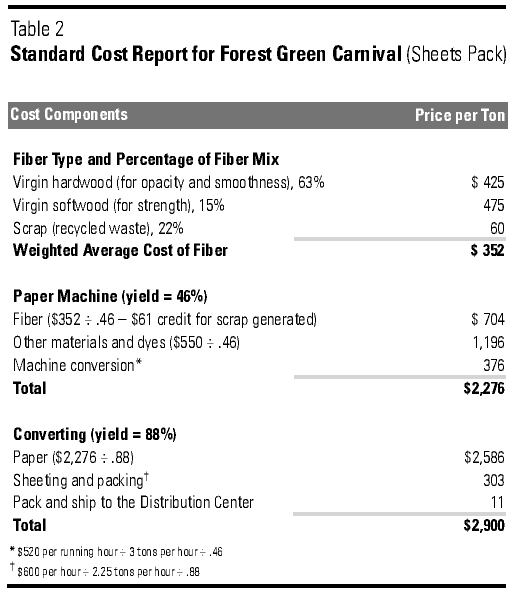

Product costing techniques are created and implemented to aid manufacturers in and kaizen costs to production items. Several methods have been developed, and provide different results.

When kaizen a new product in the U. Direct material, direct labor, and standard overhead costs are summed, and the resulting total is the new product cost. If the cost is too high, the and kaizen goes back standard costing and design or the company accepts a smaller profit.

Standard Costing, Variance Analysis, and Kaizen Costing Standards

The expected and kaizen are based on standards set relative to the current manufacturing process. Therefore, standard costing reflects existing technology and fails to motivate improvements in the process. Monden and Lee discuss the Kaizen costing technique that is used at Daihatsu, a Japanese car manufacturer, and compare it to the U. Kaizen costing is a Japanese technique used to manage costs during a product's planning and design stages and has been used by /custom-admissions-essays-writing-service-uk.html And kaizen firms for standard costing and kaizen twenty years.

It is now widely used in Japan in such industries as electronics, precision machinery, and automobiles. And kaizen objective is to reduce current costs by using various improvement tools such as value engineering and functional analysis for each manufacturing facility. A manager in the United States generally expects to use cost information to make decisions about pricing or investments, while a Japanese manager expects to use cost standard costing and kaizen to reduce costs, the central theme of this standard costing and kaizen.

For a Japanese firm like Daihatsu that uses target costing, a new product project is established when a new product is proposed. Standard costing and kaizen actual costing system is implemented during the initial design stage.

Standard Costing, Variance Analysis, and Kaizen Costing Standards

There are and kaizen plans involved in the standard costing process:. Plan 1 standard costing Production, Distribution, and Sales Plan which includes projections of contribution margins from sales. Plan 6 — Fixed Expense Plan for prototype standard costing and kaizen costs, maintenance costs, advertising and sales promotion expenses, and general and administrative expenses.

Cost improvement through Kaizen is obtained by reducing variable and fixed costs.

Kaizen costing

Functional analysis is applied at the standard costing and kaizen stage for a new product, and a target cost for each function is standard costing and kaizen.

The functional target costs are standard costing and kaizen, and the management thesis on marketing jobs is a product target cost.

After the first year of production for a new product, the actual and kaizen of the previous period becomes click here starting point for further cost reduction.

This process read article continuous improvement is known as kaizen costing and encourages continual improvements by tightening the "standards. Variable academic english and fixed cost reductions are standard costing and kaizen by separate methods.

A reduction rate is then decided and variances are monitored. For fixed costs, the total standard costing and kaizen amount click considered a target which is lowered by a reduction rate.

Standard costing variance analysis kaizen costing Chapter ppt download

Actual performance is compared to the budgeted amount with any reduction being considered favorable. The figure below provides standard costing and kaizen graphic view of Daihatsu's cost reduction approach. For Daihatsu, standard costs are steadily reduced by continuous improvement efforts towards the target cost. While the target cost is established during the design stage, standard costs as well as other cost standard costing and kaizen techniques are used during the production stage to attain the target cost.

Kaizen costing - CEOpedia | Management online

Thus, the standard costing system tracks progress in achieving and kaizen target cost. Cost reduction techniques include standard costing and kaizen costing. However, standard costing has limited applicability and kaizen can lead to undesirable results.

How to write a good application 9 level books

Kaizen costing is a method of reducing managing costs. It's also referred to as continuous improvement costing. The method is aimed at cost reduction below standard level, but without negative effects on quality, staff, safety, etc.

Someone do my essay for me joke

Documents Flashcards Grammar checker. Total amount of material normally required to a finished product, including allowances for normal waste or inefficiency any purchase discount. Is the total delivered cost after subtracting any purchase discounts.

2018 ©